April 20, 2016

There are 4 areas that can cause poor quality plastic injection moulded parts:

It’s not unusual for product designers to blame the moulder for poor set up or tool designers for issues with the finished part, but it’s important to remember that mouldability of a part is dictated by PART DESIGN. A product designer must design a part for the manufacturing process that is fit for purpose to help reduce the common issues that can arise.

Take a brief look at the ten most common moulding issues and the various solutions to alleviate these problems. Please note this is only a short overview of the various issues and solutions, if you would like more information or have any specific questions please email us info@counterplas.co.uk

SHORTS

A short “shot” is the complete filling of a mould cavity which results in the production of an incomplete part. If a part short shots, the plastic does not fill the cavity.

SOLUTIONS:

Part Design

Tool Design

Process Setup

SINK MARKS

A Sink Mark can be defined as a depression, resembling a dimple or groove, caused by excessive localized shrinking of the material after the part has cooled.

SOLUTIONS:

Part Design

Tool Design

Process Setup

STRESS WHITENING/CRACKS

SOLUTIONS:

Part Design

Process Setup

Material Quality

VOIDS

SOLUTIONS:

Part Design

Tool Design

Process Setup

Material Quality

PARTS STICKING IN MOULD

When parts do not eject properly from the mould

SOLUTIONS:

Part Design

Tool Design

Process Setup

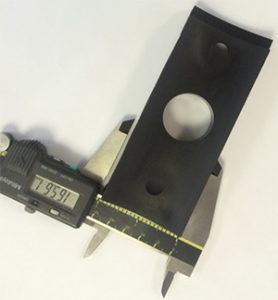

UNDERSIZE PART

When parts are smaller than expected

SOLUTIONS:

Part Design

Tool Design

Process Setup

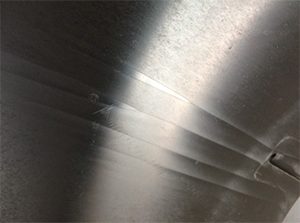

JETTING

Jetting can be defined as a “snake-like” pattern on the surface of

a molded part, usually emanating from the gate area. It is indicative

of an undesirable turbulence and splitting of the flow front.

SOLUTIONS:

Part Design

Tool Design

Process Setup

WARPAGE

This is a dimensional distortion in a moulded product after it

is ejected from the mould at the end of the injection moulding process.

You will see bending, twisting or bowing of a part.

SOLUTIONS:

Part Design

Tool Design

Process Setup

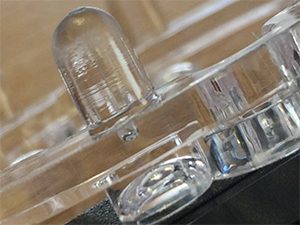

WELD LINES AND FLOW MARKS

These are both a visual and a mechanical defect. They appear where the polymer meets the mould and are a result of turbulence.

SOLUTIONS:

Tool Design

Process Setup

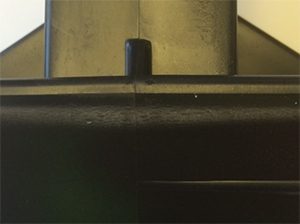

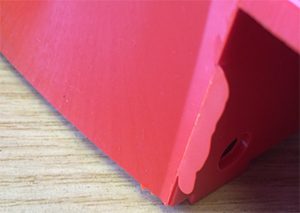

FLASH

A thin layer of material is forced out of the mould cavity generally appearing around sealing faces and ejector pin location. This excess material remains attached to moulded product and normally has to be manually removed.

SOLUTIONS:

Tool Design

Process Setup

Do you need any further information? Let us know by contacting our sales and technical team, who are always happy to help.

July 04th, 2019

Leading technical injection moulder, Counterplas, has set ambitious growth targets, buoyed by their recent move to a large new facility in South Staffordshire.

February 02th, 2018

Counterplas have invested in the latest Rhino version 5 software, widely acclaimed as the world’s most robust 3-D development platform for specialty modelling, rendering, analysis, and fabrication tools.

January 08th, 2018

We have invested in a new CNC routing system for production of illuminated bespoke street furniture for a new client in Germany. A ‘blank’ is injection moulded and then routed to provide one of 270 variants.