July 16, 2016

New Product, new moulder?

5 good reasons why.

We hear all the time that companies stay with plastic injection moulders even ones they aren’t particularly happy with, because the pain of moving all those tools, paying all outstanding bills and the teething period a new relationship brings, just seems like too much hard work and they’d rather stop with ‘the devil they know!’

What Counterplas have found when talking to companies who have a new product being designed, it’s an easier starting point for a new relationship, as it doesn’t have all the complications involved in breaking up with the incumbent moulder.

Developing a new product together is a much better way of eventually moving away from your moulder that you’re not happy with.

5 good reasons why…

Have you a new product planned for 2016?

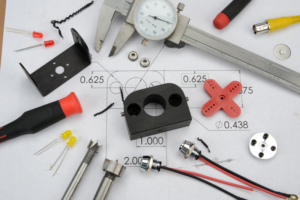

Then consider Counterplas as your new value added moulding and product assembly partner to help you develop your new product, we have a proven track record in helping companies do this.

For a free consultation to discuss your new product, please email sales@counterplas.co.uk marking it F.A.O Mark Brazier or contact our sales and technical team.

July 04th, 2019

Leading technical injection moulder, Counterplas, has set ambitious growth targets, buoyed by their recent move to a large new facility in South Staffordshire.

February 02th, 2018

Counterplas have invested in the latest Rhino version 5 software, widely acclaimed as the world’s most robust 3-D development platform for specialty modelling, rendering, analysis, and fabrication tools.

January 08th, 2018

We have invested in a new CNC routing system for production of illuminated bespoke street furniture for a new client in Germany. A ‘blank’ is injection moulded and then routed to provide one of 270 variants.